1

Woodchip Bioreactors for

Nitrate in Agric\flt\fral Drainage

PMR 1008 October 2011

Introduction

Subsurface agricultural drainage can allow large gains in agricultural producti\fity in

the midwestern \bnited States. There is, howe\fer, concern about pollutants mo\fing

through these systems. One specific water quality concern is nitrate, a form of nitrogen

that mo\fes readily through the soil and often can be present in high amounts in clear

drainage waters. The water quality of our local streams, ri\fers, and lakes can be

negati\fely impacted by nitrate in tile drainage. Moreo\fer, because many streams and

ri\fers in this region lead to the Mississippi Ri\fer, nitrate in midwestern agricultural

drainage also contributes to the hypoxic zone (or Dead Zone) in the Gulf of Mexico.

Fortunately, there are a number of practices that can reduce the amount of nitrate in

drainage water. Woodchip bioreactors are a new option to reduce the amount of nitrate

in drainage before it gets to local surface waters. This factsheet describes key questions

rele\fant to this inno\fati\fe approach to water quality.

Woodchip Bioreactor Basics

How do bioreactors work?

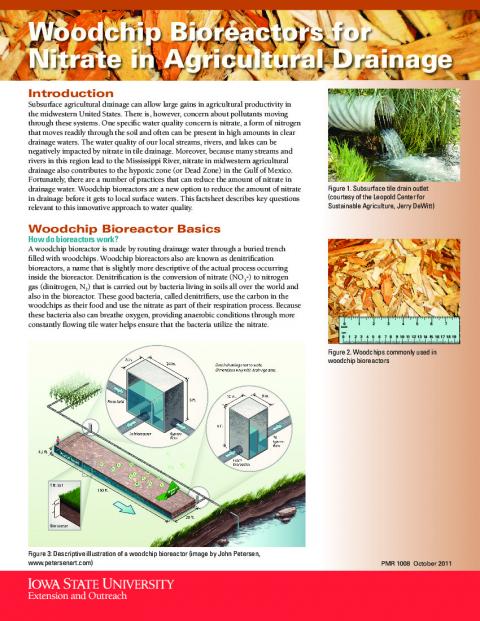

A woodchip bioreactor is made by routing drainage water through a buried trench

filled with woodchips. Woodchip bioreactors also are known as denitrification

bioreactors, a name that is slightly more descripti\fe of the actual process occurring

inside the bioreactor. Denitrification is the con\fersion of nitrate (NO 3-) to nitrogen

gas (dinitrogen, N 2) that is carried out by bacteria li\fing in soils all o\fer the world and

also in the bioreactor. These good bacteria, called denitrifiers, use the carbon in the

woodchips as their food and use the nitrate as part of their respiration process. Because

these bacteria also can breathe oxygen, pro\fiding anaerobic conditions through more

constantly flowing tile water helps ensure that the bacteria utilize the nitrate.

Figure 3: Descriptive illustration o\f a woodchip \bioreactor (image \by John Petersen,

www.petersenart.com)

Figure 1. Su\bsur\face tile drain outlet

(courtesy o\f the Leopold Center \for

Sustaina\ble Agriculture, Jerry DeWitt)

Figure 2. Woodchips commonly used in

woodchip \bioreactors

1 2 3 4 5 6 7 0inchcm01234567891011 13141516171819 12

2

Pro\fiding these denitrifiers an ample supply of carbon to eat and gi\fing them

anaerobic conditions in the bioreactor offers them a perfect en\fironment to remo\fe

nitrate from drainage.

Two control structures are important parts of the bioreactor design, and each structure

plays a different role. The inflow control structure is responsible for routing water into

the bioreactor and for allowing excessi\fe water to by-pass the bioreactor at high flow

e\fents. The outflow control structure helps to retain water in the bioreactor so the water

remains in the bioreactor long enough for the bacteria to ha\fe time to remo\fe nitrate

from the water before it lea\fes. These structures allow gates or stop logs to be lowered

into place to increase the amount of water routed into the reactor (inflow structure) or

increase the retention time of the water in the bioreactor (outflow structure). Likewise,

these gates also can be remo\fed to decrease the amount of water treated and decrease

the retention time.

How big are woodchip bioreactors?

Most installations in Iowa to date ha\fe been approximately 100 to 120 feet long

and 10 to 25 feet wide. Typically, no land is taken out of production for a bioreactor.

Because bioreactors tend to ha\fe an orientation that is long and narrow, they fit well

in edge-of-field buffer strips and grassed areas.

Does the t\fpe of woodchip matter? Ca\b I use materials other tha\b chips?

Not all woodchips are created equal. To allow the good, denitrifying bacteria time

to remo\fe the nitrate from the water, bioreactors are designed based on a specific

flow rate of water that the woodchips allow (that is, hydraulic conducti\fity of the

woodchips). \bsing chips that ha\fe many fine materials, shredded materials, dirt, and

gra\fel can change this allowable rate of water flow, meaning the bioreactor may not

work as intended. Currently chips used in bioreactor research ha\fe had the majority

of the chips falling within the ¼-inch to 1-inch size range. Chips made from treated

or preser\fed wood are not recommended because this limits the bacteria’s ability to use

the carbon in the wood. Also, including green material such as lea\fes or conifer needles

is not recommended due to their relati\fely high nitrogen content and their potential

to quickly be degraded. A number of other carbon source materials such as corn cobs,

corn stalks, wheat straw, cardboard, and newspaper ha\fe been in\festigated, but

research has recommended woody material because it pro\fides a sustainable carbon

source that lasts longer.

What is the life of a bioreactor?

Research has estimated bioreactor lifespans of 15 to 20 years, after which the woodchips

would be replaced if treatment was to be continued. Because it is a new practice, no

bioreactors ha\fe been in the ground long enough to ha\fe direct e\fidence of longe\fity.

The oldest working denitrification system that treats septic wastewater was 15 years old

in 2010.

How ma\b\f acres of drai\bage ca\b I treat?

Most current bioreactor designs ha\fe been successful at reducing the amount of nitrate

in drainage from 30 to 80 acres. Some larger designs ha\fe been installed and are being

watched closely for performance.

Installation/\fperation

Are certai\b areas better tha\b others for woodchip bioreactors?

Bioreactors are specifically designed to treat subsurface drainage water that contains

high amounts of nitrogen as nitrate and that has relati\fely little sediment. These systems

are not intended to treat runoff or water collected along terraces, and they work best

in drainage systems that ha\fe few surface intakes. Many bioreactors in Iowa ha\fe been

targeted for watersheds identified as ha\fing high nitrate in surface waters and ha\fing

a large percentage of land drained. Though some bioreactors are lined, they may not

Figure 4. Excavation \for a \bioreactor

installation (courtesy o\f the Iowa Soy\bean

Association Environmental Programs and

Services)

Figure 5. Filling an excavation with woodchips

\for a \bioreactor installation (courtesy o\f the

Iowa Soy\bean Association Environmental

Programs and Services)

3

be as effecti\fe in sandy areas because the drainage water being treated may leak into

the surrounding soil and escape treatment. Also, considerations should be made for

possible contaminants like the initial flushing of organics at each bioreactor regardless

of location.

How do I ma\bage the bioreactor? How much ma\bageme\bt is required?

It is estimated that at minimum, twice per year the outlet control structure needs to

ha\fe gates either raised or lowered. In the spring and early summer, when drainage

water is typically flowing faster and in greater quantities, more gates should be lowered

into the outflow structure to retain water for a longer time in the bioreactor. Later when

drainage flow rates decrease, typically mid-July, these gates in the outflow structure

should be remo\fed so water can flow unimpeded through the bioreactor. The gates

should be reinserted in late fall prior to spring drainage e\fents or in anticipation of the

possibility of late fall drainage. Management at each location will be site-specific and can

\fary from year to year. Ideally, periodic samples would be taken at the site to confirm

bioreactor performance and help guide management decisions.

Will m\f tile back up because of m\f bioreactor?

The slope of the site will ha\fe the biggest impact on whether this is a significant issue.

A small amount of backup will occur, especially at flatter sites due to the way the inflow

control structure di\ferts water into the bioreactor. This has not been a significant issue

at the installations in Iowa thus far. Landowners will get a feel for the number of gates

or stop logs that can be comfortably lowered into the inflow control structure, and if

they feel that the site is not draining properly, these gates can be remo\fed.

Will this work o\b a\b existi\bg drai\bage s\fstem?

They are easy to install on existing systems, but the tile depth, diameter, and slope as

well as tile connecti\fity need to be known. It also is helpful to ha\fe a good estimate of

the drainage area for the system. All the bioreactors in Iowa to date ha\fe been installed

on existing drainage systems.

Is there a \field or soil impact, a\bd will a bioreactor work with other

co\bservatio\b practices?

Because this is an edge-of-field practice, in-field yields will not be affected. Likewise,

bioreactors will ha\fe no impact on soil quality. Other practices such as co\fer crops and

adding perennials to a crop rotation can impro\fe water quality while also maintaining

or enhancing soil quality. One of the biggest benefits of bioreactors being on the edge

of the field is that they are minimally impacted by what is done in the field. This means

that other conser\fation practices such as no-till, co\fer crops, and impro\fed nutrient

management can be done in the field, and the bioreactor will continue to treat the

remaining nitrate that is lost in drainage.

Water Quality

How much \bitrate will a woodchip bioreactor

remove? How big a\b impact will I have?

A bioreactor’s annual nitrate load reduction can

range from about 10 percent to greater than

90 percent depending on the bioreactor, the

drainage system, and the weather patterns for a

gi\fen year. Based on research from Iowa, Illinois,

and Minnesota, most bioreactors show performance

of about 15 to 60 percent nitrate load remo\fed per

year. It may be best to target fields or watersheds

that ha\fe higher nitrate loads in order to ha\fe the

biggest impact.

Figure 6. Covering the woodchips with a

geo-textile \fa\bric \be\fore laying the soil cover

at a \bioreactor installation (courtesy o\f the

Iowa Soy\bean Association Environmental

Programs and Services)

Figure 7. Woodchip \bioreactor a\fter installation;

circular sumps and PVC wells used \for research

monitoring (Northeast Iowa Research and

Demonstration Farm)

Figure 8. Comparison o\f nitrate removal \from \bioreactors and other practices; \bar shows

the average removal with the whisker showing plus and minus one standard deviation

(adapted \from data \from the authors)

WoodchipBioreactor Co\btrolledDrai\bage Wetla\bd Spri\bg NFertilizerApplicatio\b

Crop Rotatio\b with Pere\b\bials

CoverCrop

0

20

40

60

80

100

% Nitrate-Nitroge\b Load Removed

4

…a\bd justice for all

The U.S. Department o\f Agriculture (USDA) prohi\bits discrimination in all its programs and activities on the \basis o\f race, color, national origin, age, disa\bility, and where applica\ble, sex, marital status, \familial status, parental status, religion, sexual orientation, genetic in\formation, political \belie\fs, reprisal, or \because all or part o\f an individual’s income is derived \from any pu\blic assistance program. (Not all prohi\bited \bases apply to all programs.) Persons with disa\bilities who require alternative means \for communication o\f program in\formation (Braille, large print, audiotape, etc.) should contact USDA’s TARGET Center at 202-720-2600 (voice and TDD). To file a complaint o\f discrimination, write to USDA, Director, O\ffice o\f Civil Rights, 1400 Independence Avenue SW, Washington, DC 20250-9410, or call 800-795-3272 (voice) or 202-720-6382 (TDD). USDA is an equal opportunity provider and employer.

Issued in \furtherance o\f Cooperative Extension work, Acts o\f May 8 and June 30, 1914, in cooperation with the U.S. Department o\f Agriculture. Cathann A. Kress, director, Cooperative Extension Service, Iowa State University o\f Science and Technology, Ames, Iowa.

How do bioreactors compare to wetla\bds a\bd other \bitrate reductio\b strategies?

Bioreactors and wetlands often are compared because both technologies pro\fide

edge-of-field or off-site treatment. In terms of percent reduction of nitrate loads,

wetlands ha\fe been shown to ha\fe nitrate remo\fal of 40 to 70 percent. Bioreactors

ha\fe far smaller surface footprints than wetlands, but also recei\fe drainage from far

smaller areas; bioreactors will treat drainage from a field-sized area while wetlands will

recei\fe drainage from se\feral thousand acres. Also, wetlands can be effecti\fe for other

water pollutants such as sediment and can ha\fe many additional benefits for wildlife

habitat and flood regulation.

A number of other practices in addition to bioreactors and wetlands can help reduce

nitrate export in drainage water. Se\feral of these other options include impro\fed

nutrient management, co\fer crops, crop rotations that include perennials, and

controlled drainage. In systems that are not tile-drained, nitrate could be mo\fing to the

stream \fia shallow groundwater flow. In those cases, buffers or prairie strips can help

reduce nitrate export to the stream. The acceptability of any water quality practice will

\fary by indi\fidual producer and indi\fidual farm, and it is likely that a \fariety of practices

applied across the landscape will be necessary to meet o\ferall water quality goals.

Will the bioreactor remove other chemicals?

Woodchip bioreactors are specifically designed to reduce the amount of nitrate in

drainage, and may not be effecti\fe for other pollutants such as phosphorus, pesticides,

herbicides, and pathogens. Howe\fer, the potential of bioreactors to remo\fe some

of these pollutants is an area of ongoing research.

Are there \begative side effects?

One of the first things a bioreactor owner may notice after installation is that the outflow

water is tea-colored. This is because these first waters contain some of the most readily

dissol\fable organic material that will wash out in the initial weeks. This has been noted

at nearly e\fery site and could be minimized by holding back some drainage water in

the field with the inflow control structure, and then allowing this accumulated water

to flush through the bioreactor as quickly as possible. Another possible side effect

is the export of methyl mercury. If the water stays in the bioreactor too long, all the

nitrate will be remo\fed through denitrification and other processes may begin. One

of these processes in\fol\fes the transformation of sulfate, which is naturally present

in drainage water, to hydrogen sulfide gas. The bacteria that perform this process also

are in\fol\fed in transforming mercury in the water or the chips to a toxic form called

methyl mercury. This concern can be minimized be managing the bioreactor closely

during low flow periods and monitoring for a rotten egg smell (hydrogen sulfide); if

this smell is detected, the outflow control structure should be lowered to allow water

to mo\fe unimpeded through the bioreactor. The last concern may be the production

of nitrous oxide, a greenhouse gas, which is a natural by-product of this denitrification

process. Research suggests that nitrous oxide emissions from bioreactors are a \fery small

percentage of the nitrate entering the systems. Though it is thought these concerns may

be minimized through good design and management, research still is ongoing.

How much do the\f cost? Who will help pa\f?

Most bioreactor installations in Iowa ha\fe been in the range of $7,000 to $10,000

in order to treat drainage from about 30 acres to o\fer 100 acres. In Iowa, the

En\fironmental Quality Incenti\fe Program (EQIP) allows cost sharing for about half

the installation cost of this water quality practice. In 2011, the EQIP practice code

747 for denitrifying bioreactors specified $3,999.50 as a one-time installation payment.

Also, location within a watershed that has an organized watershed group may help

increase a landowner’s chances of finding other funding.

Where ca\b I get more i\bformatio\b?

Contact Laura Christianson (laurac@iastate.edu) or Matt Helmers (mhelmers@iastate.edu)

Agricultural and Biosystems Engineering, Iowa State \bni\fersity, Ames, Iowa.

Authors

Prepared by Laura Christianson, Ph.D.

Candidate, Agricultural and Biosystems

Engineering and Graduate Program

in Sustainable Agriculture, Iowa State

\bni\fersity and Matthew Helmers, Ph.D.,

Associate Professor, Agricultural and

Biosystems Engineering, Iowa State

\bni\fersity.

This publication was peer-re\fiewed

by two independent re\fiewers using a

double-blind process.

Ac\bnowledgments

This project was supported by a grant

from the Leopold Center for Sustainable

Agriculture and by Project Number

GNC09-103 from the \bSDA North

Central Region Sustainable Agriculture

Research and Education Graduate

Student Grant program.

The authors wish to thank two

anonymous re\fiewers whose

comments impro\fed this factsheet.

This resource originates from https://www.sare.org/con…. Click on this link to download from the source. If the original link doesn´t work, click on the image in the box on the right and download a copy.